RVR - Recirculating Roller Screws

RVR - Recirculating Roller Screws

RVR Recirculating Roller Screws

RVR Recirculating Roller Screws

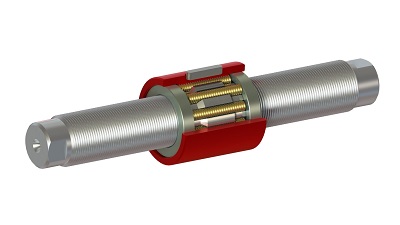

A recirculating roller screw is a planetary roller screw because the rollers orbit the shaft. However, the inner mechanism is special.

What makes the recirculating design different is that the rollers are ground with no thread angle and so they travel axially within the nut and reset - or recirculate - after each orbit. This type of operation provides exceptionally precise linear motion.

A key to RVR roller screw operation is the carefully engineered cage that houses the grooved rollers and cam system which indexes the rollers precisely.

The RVR design offers very high rigidity. Rollvis are able to offer preloaded designs when added axial rigidity is required.

|  |

|

Features

| Benefits

|

Advantages

What RVR recirculating roller screws lack in maximum speed and acceleration, they make up for in resolution, strength and stiffness.

- The RVR recirculating design allows customers to choose much smaller drive motors while still being able to support very high loads due to the ultra-small leads

- The high rigidity, efficiency and positioning accuracy allows the customer to use a single screw for both macro and fine positioning

- The ultra fine leads also mean that the torque required to hold a position against back driving is much lower which can affect both the motor and brake selection

RVR roller screw systems are ideal for low or medium-speed linear movements where precision is critical.

Applications

| Industries

|

State-of-the-Art Control Solutions

Rollvis is a trusted industry leader in precision linear motion systems. Rollvis engineer customized automation parts for advances applications in science, metalworking, aerospace, automotive, semiconductor, medical device manufacturing, and many other fields.